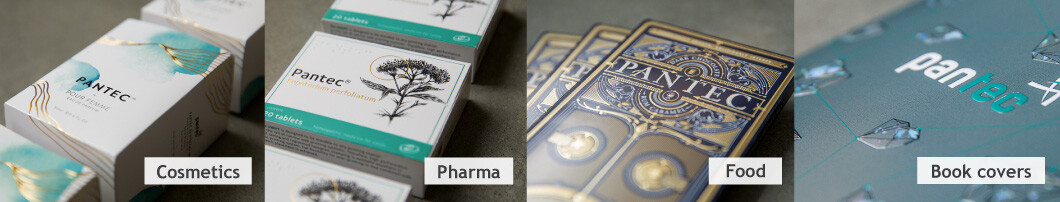

Packaging for cosmetics, pharma, chocolate, tobacco or books can be manufactured within a day and up to 50% less waste

Deliver luxury packaging faster to a more competitive price

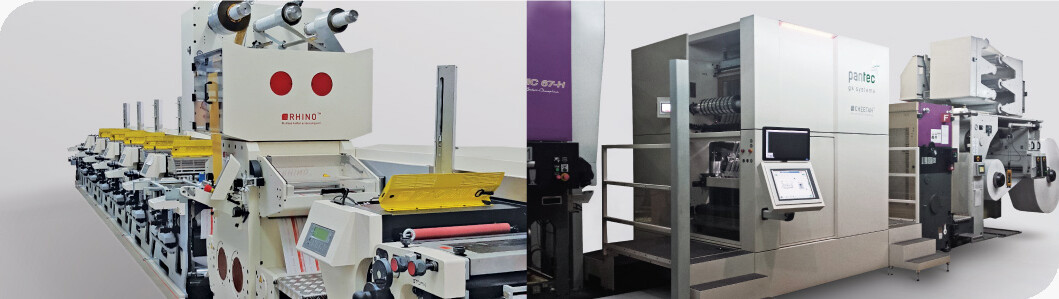

To date high-quality luxury packaging are very expensive to manufacture, since the process is usually divided into several process steps. The refining with hot foil, holograms and embossing takes place in separate machines, which splits the entire manufacturing process in several sub processes. This often means complex, time-consuming logistical processes and much waste. New high-performance finishing machines for web speed up to 150 m/min - such as the rotary hot foil stamping system CHEETAH™ or the flatbed embossing system RHINO™ by Pantec GS Systems opens up completely new possibilities for luxury packaging printers for low cost production and a substantial reduction of lead times.

Sheet fed high quality packaging with hot foil, embossing and holographic patches, or security features are now expensive and time-consuming to produce - with web processing it's fast and cost effective.

Traditional off-line production: time consuming and expensive

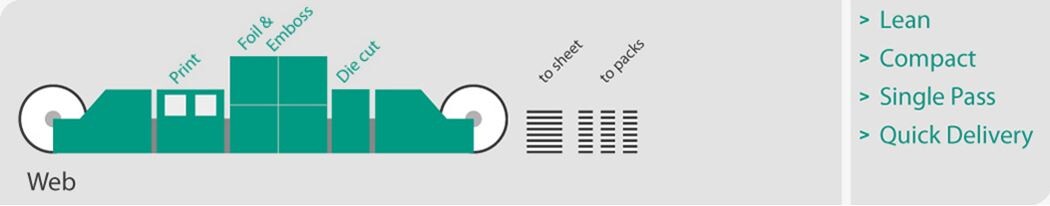

Today, a typical production process for high-quality packaging usually comprises three essential process steps. In the first step, the substrate is printed on web or sheet-fed presses, followed by hot foil refining in the second step, eventually combined with embossing. Sometimes embossing is even a separate process. In the last step, the cartons are die cut.

Each sub-process adds waste, setup time and time to check before production start. With every step the risk to waste valuable stock of the previous work increases. Printers experience 50% or more waste on small batch sizes. Moreover, the lead time of the order is very high due to transfer, waiting and setup time.

Web Processing: the key to fast delivery and low waste

Today completely new in-line production concepts for packaging can be applied. In-line means: printing, foiling, embossing, die cutting, all done in a single pass to the finished packs. One-time machine set up and one-time "good for print" reduces the risk and the waste and results in a short lead time at a much better cost structure!

High performance in-line hotfoil systems like RHINO™ (left) and CHEETAH™ (right) allow single pass manufacturing of luxury packagings with complex foil designs