Embellishment technologies to win the battle on the shelf

Metallic effects

Gold foil, applied on PP in rotary stamping

In addition to emphasising characters or elements (in this case the preprint was embossed), blind embossing also allows the embossing of customized structures.

3D foil embossing (transparent foil)

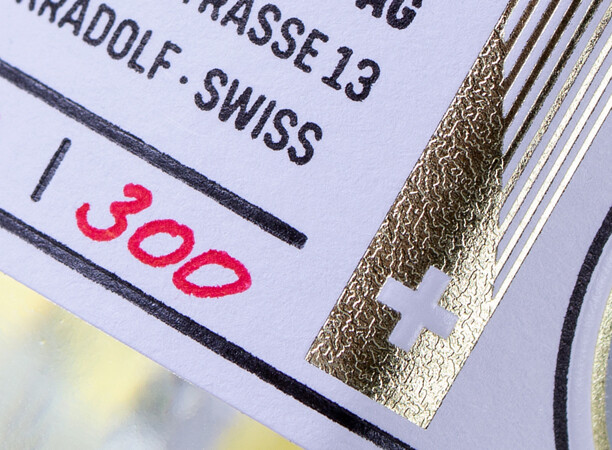

Textured foil embossing on self-adhesive labels

Security patch with foil microembossing, based on holo lens, gold and transparent foil

3D effect lens, perfectly placed on the printing

Spatial FX image, placed on PP in rotary stamping

3D foil embossing (black foil) surrounded with fine line foiling

Experience the design and haptic effect of highly embellished labels and packaging.

Request your free Pantec sample package today so that you can "grasp" the opportunities offered by embellishments in the truest sense of the word as early as next week.