Embellish packaging with rotary technology

Packaging is an important part of the marketing mix and reflects the value of the product. Any packaging can easily and cost-effectively be transformed into a high-value marketing tool with rotary technology.

Embellishment options with rotary technology

Metallic effects

Placement of lenses

Placement of 3D Images

®

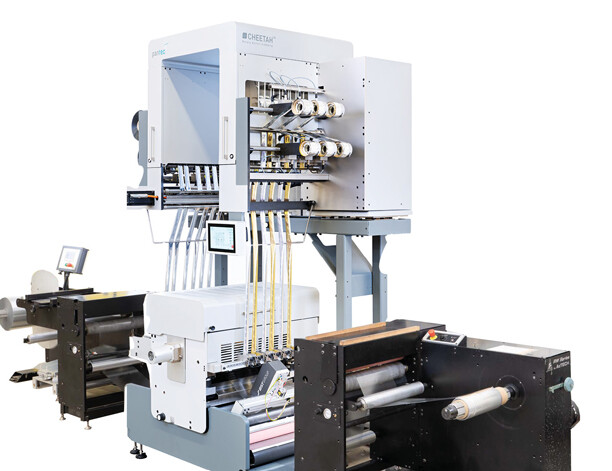

CHEETAH® N 410 / 570

-

for in-line production in the label industry

-

for small to medium runs in the shrink sleeve industry (in-line or off-line)

CHEETAH® W 850 / 1060

-

for long runs in der folding carton industry (in-line or off-line)

-

for long runs in the shrink sleeves industry (off-line)

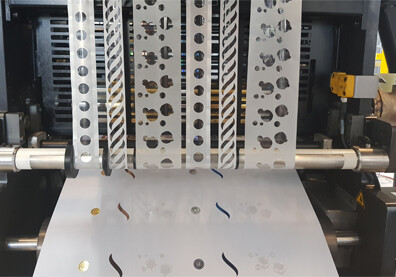

Exciting 3D effects on thin substrates and shrink sleeves

3D images are an attractive embellishment option for substrates that can't be embossed due to the material thickness or the downstream process.These are customer-specific designed images that are applied directly to a substrate. The customised 3D image is placed on the substrate through heat and pressure from a carrier film which has a register mark on it.

High quality meets high efficiency

One generic image foil for all repeats

Pantec

Conventional technology:

One specific foil for each label repeat length– high waste

:

One generic

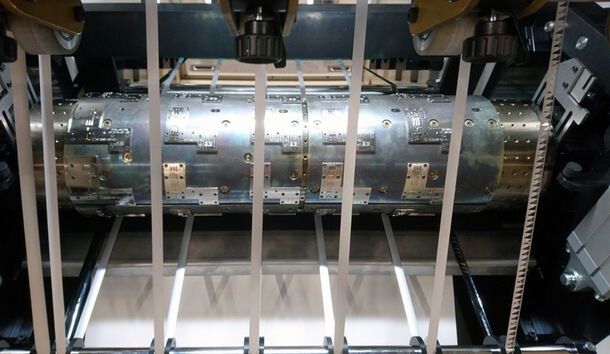

Pantec’s rotary technology runs with up to 20 cycles per second. Foil, lenses or 3D Images are placed individually in register with hardly any waste in between. This high moving frequency is only possible thanks to the unique Pantec vaccum foil motion technology and the precise, dynamic servo control used.

An intuitive, user-friendly HMI makes it eas®

-

®

-

-

-

® can be accessed remotely, giving Pantec the opportunity for fast and easy support. Whether there is a technical problem or the need for assistance in setting up the next job, the Pantec support is only just a click away.

CHEETAH® N 410/570

CHEETAH® N

Key data CHEETAH® N 410/510

CHEEATH® N

CHEETAH® W 860/1060

Key data CHEETAH® W 860/1060

Which CHEETAH® fits best to you? Let´s talk to find out!

René Abächerli

Office: +41 71 5210 821

Mobile: +41 79 500 82 44

Languages:

German

English

Sales Areas

Europe - UK/IRL

USA, Canada

Central Europe - Germany, Austria, Benelux, Scandinavia,

Eastern Europe - Poland, Bulgaria, Hungary, Czech Republic, Slovakia, Serbia, Croatia, Greece

Russia

North-East Asia / Near & Central Asia

Roger Meierhofer

Office: +41 71 5210 840

Mobile: +41 76 420 19 00

Languages:

German, English

French, Italian, Spanish

Sales Areas

Switzerland

Southern Europe - France, Spain, Italy, Portugal

Latin America

Middle East, Africa

India

South-East Asia

Australia, New Zealand