The power of in-line operation

Single pass: the economic enabler for complex and fancy foil embellishment

The label market has an ever lasting interest for new embellishment features. Especially in the high end segments multifoil designs, embossing features or holographics foils are required. The latest innovation is 3D registered holographic patches as eye catchers on the shelfs - another fancy technology many brand owners want to go for. Providing these features to the market is a key differentiator for label printers. The only precondition: efficient production processes. In the best case single pass with in-line equipment.

The beauty of in-line embellishment

In-line embellishment with Pantec means: equipment speed coping with the speed of the press and high sophisticated design opportunities. See the following slide show to get an impression of the beauty of efficient in-line decoration. All these samples are produced single pass at normal press speed.

In-line decoration: the key to efficiency

Traditionally high sophisticated labels are made in a complex, sequential process. For multifoil designs several passes are necessary, resulting in high wastage. The application of registered patches slows down the machine performance, traditionally.

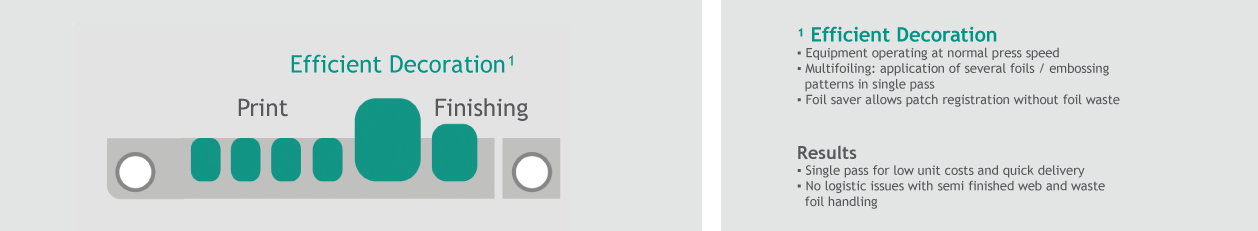

Pantec in-line equipment provides decoration with multiple foils and foil saving/registration, running at line speed which allows the manufacturing of complex designs in a single pass.

In-line production concepts for labels means: printing, (multi)foiling, embossing, all done in a single pass. One-time machine set up for complex label design reduces risk and waste and results in a short lead time at a much better cost structure!

Request your free samples!

Just drop your contact details and get amazing samples of in-line manufactured labels with outstanding multifoil and hologram designs.