Multi-stroke flat bed foiling equipment

Can you produce amazing multifoil designs competitively today?

Printers are increasingly being asked to finish high-quality labels with more than one foil. The classic variant of making several machine passes with rotary hot foil embossers is unproductive, especially with increasing volumes, and causes difficulties with different substrates. Flatbed embossing is many points ahead of rotary embossing - longer dwell times enable embossing on open substrates and allow several foils to be applied in a single machine pass.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim. Aliquam lorem ante, dapibus in, viverra quis, feugiat a,

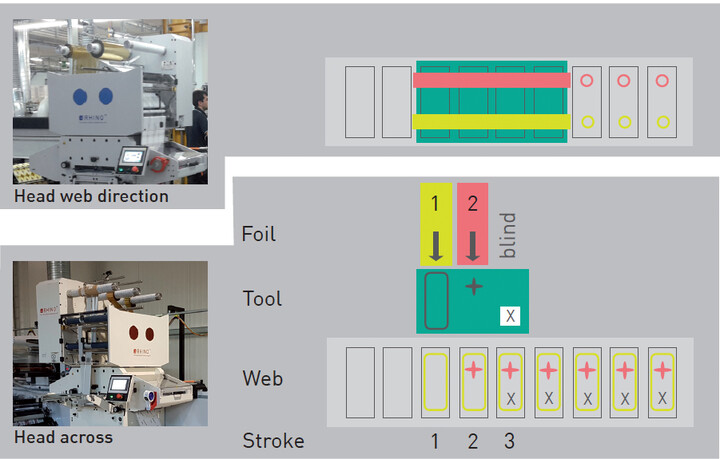

The foil head cross to the web is the key to multifoiling. This concept was already introduced by Pantec in 2010 and is now established as standard.

Multi-foil across the web - the key to efficient production of complex labels

Modern flat bed embossing systems are equipped with a rotating foil head. This enables the foil to be applied both lengthwise and crosswise in relation to the web direction (90 degree rotation of the head).Combined with Multistroke, extremely interesting design possibilities arise.

With the head crosswise, flatbed embossing systems can apply several foils in a single pass

Application of various foils crosswise

If the foil is fed to the web crosswise, multiple foil colors can be embossed successively. With Multistroke the web can be embossed in

several small steps. In doing so, the embossing can be applied one on top of the next, which enables the production of unique designs in a single pass.

Multifoil productivity - not just a matter of speed

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim. Aliquam lorem ante, dapibus in, viverra quis, feugiat a,

"we see increasing interest in multi-foil label design in all regions of the world - from spirits such as vodka, gin, tequila and wine to special applications such as postal mailings and security"

René Abächerli,

Pantec Print Decoration

Flat bed embellishment - quality drivers

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim. Aliquam lorem ante, dapibus in, viverra quis, feugiat a,

Foil consumption and job change - the biggest drivers for machine efficiency

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim. Aliquam lorem ante, dapibus in, viverra quis, feugiat a,

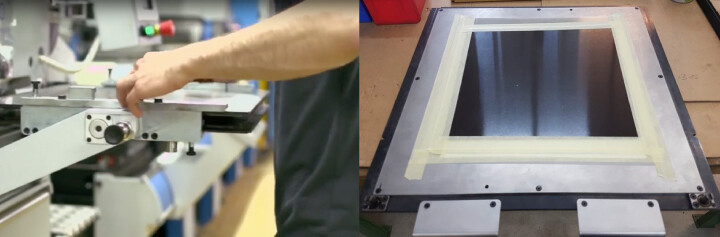

When selecting a flatbed embossing system, the changeover times - both for the initial setup and for repeat jobs - must be carefully observed. With RHINO™ , for example, Pantec offers a job saver plate with which repeat jobs can be set up in just a few minutes.