New business opportunities for label printerThe beauty of multi-foil flat bed design

The beauty of multi-foil flat bed design

There is probably no product where the label is as important as for spirits or wine bottles. A large proportion of spirits buyers make their decision as to whether to buy a particular brandy, wine or sparkling wine based on what the label looks like.

Therefore a spirits or wine label must be an eye-catcher, as it is an important part of the purchase decision. But the quality of the labels has meanwhile reached a high level in general, what makes it difficult to differentiate. Noble designs, mostly finished with hot foil, dominate today's shelves. But the more complex the embellishment become, the higher the costs involved.

To stay ahead in this battle for customer attention, manufacturers are interested in new design options without driving packaging costs to immeasurable levels.

Creative designs and novel embellishments attract the attention of potential buyers

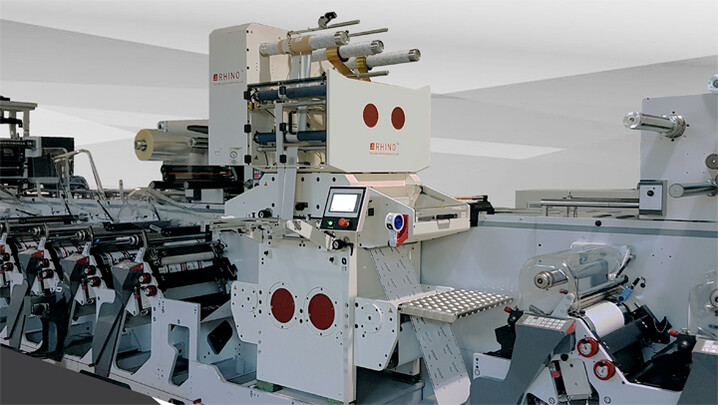

RHINO™ IIS is the answer to these requirements. The in-line flatbed embossing system offers sophisticated embellishment techniques with unrivalled performance and is thus an added value for every production line for high-quality labels.

To this day, more than 100 RHINO™ flatbed systems help label printers worldwide to differentiate and offer complex designs cost effectively. RHINO™ systems are running in almost all presses: Mark Andy, Gallus, MPS, Miyakoshi, Nilpeter, OMET, Rotatek, Lombardi and fast running offline systems.

The beauty of flat bed in-line embellishment with RHINO™ IIS

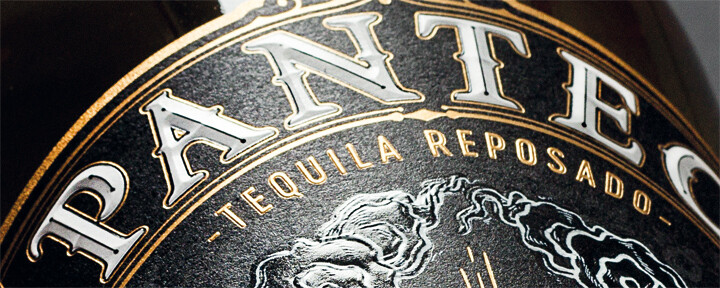

Foil stamping is a popular and effective method of refinement in the wine and spirits sector. The flatbed hot foil stamping system RHINO™ IIS raises this finishing technology to a completely new level. The multistroke process of RHINO™ IIS allows several different foils to be applied to one label in one production run. For example, several foil colors can be used to emphasize individual text modules. With Multistroke also additional accentuation of graphic elements with transparent foil can be applied.

3D microembossed gold foil for essential elements , holographic foil for accentuation and transparent foil for a spatial impression of the backgroud level make this tequila label a unique piece of art.

The robust construction of the machine as well as the combination of foil embossing and relief cutting in one tool allows the further refinement of the hot foil. In this way, the foil can be given its own structure by micro- and nano-embossing and can be placed precisely in register with other elements. This opens up completely new possibilities for graphic designers.

With the register-accurate application of holograms and lenses, RHINO™ IIS now also enables the use of the latest finishing technology.

Wether sophisticated single foil effects or complex multi-foil designs:

RHINO™ IIS provides outstanding embellishement quality and improves the cost structure of your production. The system is a valuable upgrade for every high end label production line.

Design effects with RHINO™ IIS in detail

Multistroke on single tool: Different foils in perfect register

The revolvable foil head of RHINO™ IIS allows the application of several foils in one machine pass. With a tool length of 410 mm and a label width of 10 cm, for example, up to 4 foils can be applied. With a label width of 12 cm 3 foils are possible.

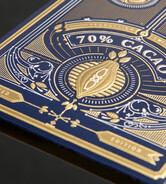

Single pass label production with 3-stroke foil decoration. The font is perfectly surrounded with a golden line, the font itself decorated with an embossed transparent foil. The 3rd foil attached is a holographic foil in the lower part of the label.

The special thing about it: since all embossing steps are on one and the same tool, there is no register deviation. This application precision results in completely new design possibilities in the use of hot foil as the adjacent example shows. In this way, specific borders can be placed around fonts or a wide variety of foil elements can be placed with the highest precision in relation to one another.

High, crisp relief

The flat embossing process is technically the only way to apply relief structures at in-line speed, especially with uncoated substrates.

With rotary application - due to the short line contact between the tool, the foil and the substrate - often 35 to 40 m/min cannot be exceeded. In addition, the production of rotary foil embossing tools is very complex and the set-up on the machine is complicated and time-consuming.

With the special design of RHINO™ IIS, the contact time is factor 7 and higher compared to rotary. This allows higher linear speeds, better transfer quality, cheaper foils and cheaper tools. Combined with the high embossing force of 60 tons and a process temperature of 180° C (356° F), inimitable relief structures can be created.

RHINO™ IIS provides long dwell time, zero register and high processing temperature resulting in outstanding 3D reliefs

Due to the special temperature/pressure/embossing time constellation during the embossing process, RHINO™ IIS changes the structure of the substrate in such a way that the relief structure remains unchanged and stable during subsequent overprinting.

See RHINO™ operating in Gallus RCS

For privacy reasons, we do not offer the playback of the video directly on our site. By clicking the button you will be redirected to Youtube. Please note that this will transfer user data to Youtube or Google. Read more about our privacy policy.

Microembossing - additional hot foil refinement for exceptional effect

Simple foil embossing has become the standard finish for high-quality labels. With RHINO™ IIS micro and nano-embossing patterns such ordinary foil embossing can be enhanced with extraordinary optical effects. For example, the look of foiled frames can be extended by roughened nanostructure. Or foiled letters of brand or product names receive a bevel shape (partly) microembossed structure.

A bevel shape and partly microembossed structure makes this lettering a real eye-catcher

Further microembossing applications are holographic looking structures, micro texts for security purpose or individual paper structures. Buyers do not consciously see this kind of embellishment, but these effects make labels stand out from the crowd.

A roughened nanostructure gives a distinguished look to a label frame

It´s the very sturdy and robust design of RHINO™ IIS making micro and nanoembossing possible, as there needs to be perfect alignment between stamping tool and counterpart. But not just that: Only in combination with the high, uniform embossing pressure and the long dwell time these extraordinary effects can be achieved.

See RHINO™ IIS in a live demo at booth 1847

Patch and hologram insetting in perfect register

Fairly new effects available in the market are the so called lenses, which generate a spatial depth with an optical effect that's hard to look away from. The lenses are available in round or angular shapes, coloured in silver, gold, or transparent.

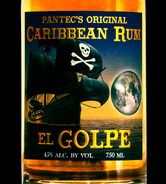

A view down onto a sealed rum bottle: the closure is printed with a compass, embellished with a lens perfectly fitting to the round shape, giving a spatial depth impression

The effect of these lenses is even more impressive if applied onto a pre-printed element as shown in the example. This application requires the lens to be applied in perfect register. With its servo controlled foil motion and extension technology plus the friction free foil motion RHINO™ IIS meets this requirement. But not just the register is perfect. RHINO™ IIS applies lenses and holograms at full in-line speed.

RHINO™ IIS at a glance

High productiviy

30´000 embossing strokes per hour

E.g. 68 m/min for 3 stroke design

High quality embossing

60 tons embossing power

6 independent heating zones / up to 180° C (356° F)

Fit for purpose

Portfolio of upgradeable machines

For rotary, semi-rotary and intermittent presses

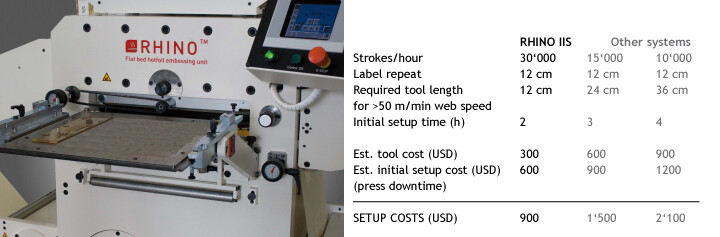

30'000 strokes per hour and fast job change - the basis for high production efficiency

With its 30´000 strokes per hour, RHINO™ IIS is the fastest flatbed embossing machine available on the market. With this high stroke rate, multi-foil designs can be produced at high in-line speeds. But also single-foil designs, which are produced in-line, benefit from the performance: the high stroke rate allows the use of very short tools. This reduces material costs and setup time - and thus the downtime of the entire press - considerably.

Speaking of downtime: Pantec offers a so-called job saver plate for repeated jobs, eliminating the time-consuming setup of the counter plate.

RHINO™ IIS: cost efficient single pass production of complex multi-stroke designs

Traditional label embellishment with hot foil has a substantial influence on production costs - and usually also increases lead times. With RHINO™ IIS the refinement process goes in-inline, allowing cost effective high end label production in a single pass.

The 30’000 strokes per hour RHINO™ IIS also cope with the latest market requirement, namely the increasing demand for higher numbers of foil effects. The machines high multistroke performance ensures also economic single pass production in future without any loss of overall press performance.

In-line production with RHINO™ IIS means: printing, (multi)foiling, embossing, all done in a single pass.

The high stroke number of RHINO™ IIS enables impressive production speeds for multi-foil designs:

2-foil designs: 102 m/min

3-foil designs: 68 m/min

4-foil designs: 51 m/min

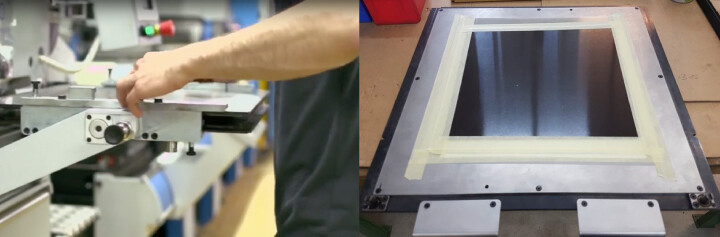

The RHINO™ job saver plate - no setup effort for repetitive jobs

The initial setup of flat bed embossing tools is known as a very time consuming job, as the shimming of the counterplate needs a countless number of trials and error.

Without the appropriate tools, this work is also required for repetitive jobs again and again. RHINO™ IIS has a solution for that. The shimming elements are applied onto a so called "job saver plate", thus the final setup of the tool is kind of stored for further jobs.

RHINO™ has a tool cassette for quick job change. In combination with the job saver counter plate the setup of the machine for repetitive jobs can be done without finetuning.

High embossing frequency allows in-line speed with short tools

As mentioned earlier, the sophisticated RHINO™ IIS embellishment features as microembossing and patch insetting help to upgrade basic label designs to a new level. But that´s not all: the production of single-stroke designs with RHINO™ IIS can be done with a short tool, which is not only cheaper, but means also much less effort for tool setup. As a result, this means significant lower production costs compared to slower in-line systems.

30'000 strokes per hour allow short tools for one-stroke designs: cheaper tool, reduced setup time

Watch it - touch it!

RHINO™ embellishments can transfer a label to a piece of art standing out of the shelves. Convince yourself with a pack of samples:

-

Tequila Label - 3-foil design: Microembossing | transparent foil / holographic foil

-

Rum Label - 3-foil design: Microembossing | transparent foil | lens in register

-

Chocolate packing: 3D hot foil embossing